The semiconductor industry continues to push technological boundaries with smaller, faster, and more complex devices. However, as manufacturing demands grow, so too does the complexity of semiconductor equipment. Optimizing these systems for thermal stability, fluid

flow, and contamination control has become vital. This is where Computational Fluid Dynamics (CFD) steps in — offering engineers the power to simulate, predict, and perfect equipment design before physical prototypes are built.

CFD is a branch of fluid mechanics that uses numerical analysis and algorithms to solve and analyze problems involving fluid flows. In the context of semiconductor equipment design, CFD allows engineers to simulate and study the behavior of gases and liquids within the equipment, enabling them to optimize processes, enhance performance, and reduce the risk of contamination. CFD can be applied to optimize the design of various critical equipment components, including:

Equipments where CFD can help optimize design:

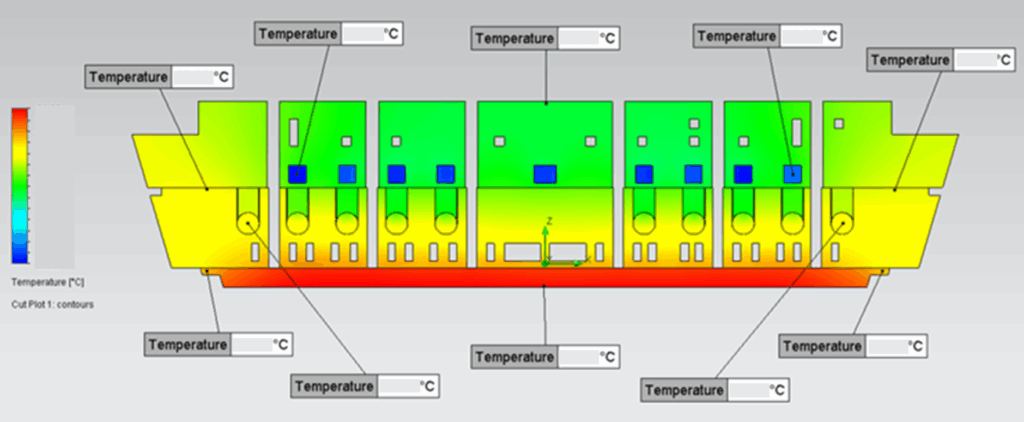

Effective thermal management is crucial in semiconductor manufacturing to prevent overheating and ensure uniform temperature distribution. CFD allows for the simulation of heat transfer within equipment, aiding in the design of efficient cooling systems. By modeling temperature gradients and identifying hotspots, engineers can optimize the placement of cooling channels and heat sinks, enhancing equipment reliability and performance.

Image: Thermal cross-section of a showerhead

One such application involved conducting finite element analysis on a showerhead component. We analysed and assessed thermal stresses and deformation under operational conditions, ensuring the component’s structural integrity and consistent function. You can download the detailed case study here – Showerhead FEA Analysis.

Image: Final heat traced design of an electrostatic chuck

Another important project focused on optimizing the heat and cooling channels within an electrostatic chuck. By simulating fluid flow and heat transfer, the design was refined to enhance temperature uniformity and prevent localized overheating for stable wafer processing. Download the full case study here – Heat and Cooling Channel Design – Analysis for an Electrostatic chuck.

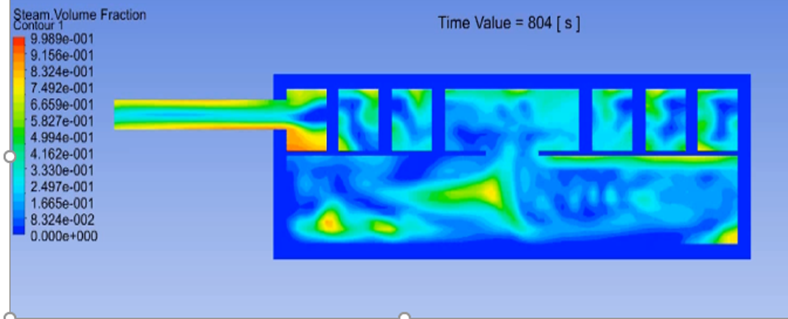

Processes like Chemical Vapor Deposition (CVD) and Plasma Etching require precise gas flow control. CFD simulations help in analyzing and optimizing gas distribution within reaction chambers, ensuring uniform deposition and etching rates. Through virtual testing of different chamber designs and flow rates, engineers can achieve optimal gas flow patterns, improving process efficiency and yield.

Image: Volume fraction contour of water vapor inside a boiler

AES conducted a transient coupled thermal and CFD study on a high-pressure boiler, focusing on achieving steam temperatures of 350°C at pressures of 15, 20, and 25 atm. This project included complete thermal mapping to support design optimization. You can download the case study for more details – Boiler Simulation.

CFD is instrumental in designing and optimizing cleanroom environments, ensuring controlled temperature, humidity, and airflow conditions. Simulations help in evaluating the performance of HVAC systems, identifying potential areas of turbulence or stagnation, and ensuring compliance with cleanliness standards. Understanding and managing these airflow patterns is also key to controlling particle contamination.

Maintaining a contamination-free environment is vital in semiconductor manufacturing. CFD aids in predicting particle trajectories and identifying areas prone to particle accumulation. By simulating airflow patterns and particle movements, designers can implement strategies to minimize contamination risks, such as optimizing airflow paths and incorporating effective filtration systems.

![]()

Image: Trajectories of contamination particles in the fluid stream, indicating residence time on wafer processing equipment.

In one of AES’s projects, Particle Tracking and Inspection in Semiconductor Equipment, we aimed to understand how contamination occurs and develop strategies to avoid the deposition of particles on wafers. This approach allowed us to identify key contamination sources and implement more effective control measures. You can download the detailed case study here – Particle Tracking and Inspection in Semiconductor Equipments.

Recent research has introduced multi-fidelity surrogate modeling approaches to optimize semiconductor equipment design. By combining low- and high-fidelity simulation data, engineers can achieve accurate predictions with reduced computational costs. This method enhances the efficiency of design optimization processes, enabling rapid exploration of design alternatives.

Integrating machine learning with CFD simulations facilitates the development of predictive models for equipment behavior. These models can accelerate the design process by identifying optimal design parameters and predicting performance outcomes.

By leveraging data-driven approaches, engineers can enhance the accuracy and speed of design iterations.

Benefits of CFD in Semiconductor Equipment Design

CFD has evolved from a specialized engineering tool to a mainstream necessity in semiconductor equipment design, offering precision-driven insights that reduce both development costs and risks. By integrating CFD early in the design phase, manufacturers can optimize gas flow dynamics, refine thermal management, and control particle contamination all without relying on expensive and time-consuming physical prototypes. This accelerates time-to-market while ensuring compliance with stringent industry standards for process control, yield,

and reliability.

For semiconductor equipment manufacturers, leveraging CFD means staying competitive in a market driven by innovation, miniaturization, and operational efficiency. Investing in high-fidelity CFD tools and expertise can help organizations accelerate equipment development, reduce design risks, and deliver solutions that meet the highest standards of performance. The future of semiconductor manufacturing belongs to those who embrace digital simulation, and CFD is at the core of this transformation. By integrating our CFD solutions into your equipment development process, you can innovate faster, optimize performance, and maintain your leadership in the industry. Contact us now!