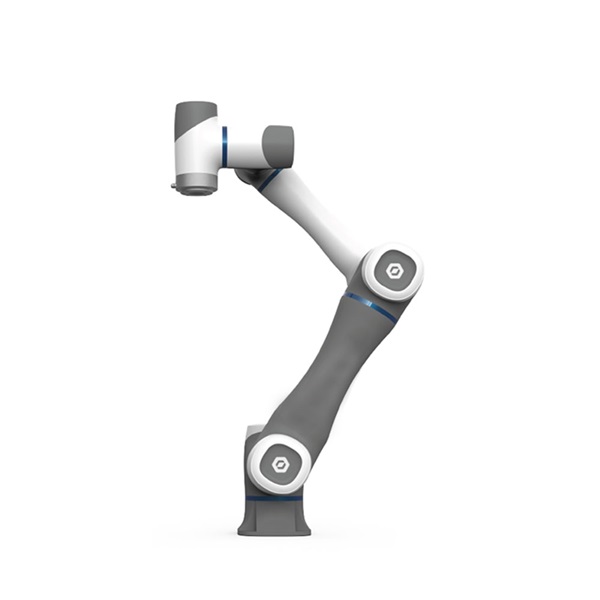

In today’s rapidly evolving technological landscape, Collaborative Robotics, often referred to as COBOTS, stands at the forefront of innovation, reshaping industries and transforming the way we work. Unlike their traditional counterparts, COBOTS are designed to work alongside humans, fostering a synergistic relationship between man and machine. This blog aims to delve deep into the transformative potential of COBOTS, tracing their evolution, exploring their diverse applications, discussing the profound impact they have on bridging the gap between humanity and technology, and addressing the ethical and societal implications associated with their adoption.

The history of robotics is a testament to human ingenuity and innovation. While the concept of robots dates back centuries, it wasn’t until the mid-20th century that industrial robots made their debut, primarily in manufacturing settings. These early robots were characterized by their rigid programming and limited autonomy, operating within predefined parameters and often isolated from human workers. However, as technology advanced, so did the aspirations for robotics. Researchers and engineers began exploring ways to make robots more adaptable, intelligent, and collaborative.

This led to the development of COBOTS, which represent a paradigm shift in the field by prioritizing human-robot interaction and cooperation.

COBOTS are equipped with an array of advanced sensing technologies and AI algorithms, enabling them to perceive and interact with their environment in a manner akin to humans. COBOTS are a type of robot that is unique for its motion capabilities and built-in environmental detection. These collaborative robots are so-named because they can adjust their movements based on their surroundings. Additionally, COBOTS are designed with safety features that protect operators working near them, including electrical and physical braking systems. Furthermore, they use internal redundant designs

to ensure that they shut down completely in the event of control errors or other failures.

The versatility of COBOTS extends far beyond the confines of traditional manufacturing. In healthcare, COBOTS are revolutionizing patient care by assisting surgeons in delicate procedures with unparalleled precision and reducing the risk of human error. Similarly, in logistics and warehousing, COBOTS streamline operations by automating tasks such as inventory management and order fulfillment, thereby enhancing efficiency and reducing costs. Moreover, in the semiconductor industry, COBOTS play a crucial role in semiconductor manufacturing processes, handling intricate/challenging tasks like precision assembly, PCB testing and delicate material handling.

In a similar vein, AES undertook a notable project, COBOT CR-5 on “Non-invasive PCB Inspection System,” for a leading semiconductor company in the United States. AES engaged in extensive research and development to embed a robotic system capable of autonomously detecting distinctive signals from a Device Under Test (DUT), eliminating the need for human intervention. We achieved a sensing repeatability of ±1% for various parameters, such as temperature sensing, RF probes, and optical camera inspection. Watch the COBOT CR-5 in action,

Click here for the real-time demonstration video.

The adoption of COBOTS brings forth a multitude of benefits for both businesses and society at large. The usage of COBOTS will lead to the following benefits,

Despite the myriad benefits of COBOTS, there are legitimate concerns surrounding their widespread adoption. Chief among these concerns is the potential for job displacement, particularly in industries heavily reliant on manual labor.

However, it is essential to recognize that while certain job roles may evolve or become obsolete, the adoption of COBOTS also creates new opportunities for employment and skill development. Furthermore, ethical considerations such as privacy, algorithmic bias, and human oversight must be carefully addressed to ensure the responsible development and deployment of COBOTS. Additionally, regulatory frameworks and standards are needed to govern the use of COBOTS and ensure their safe and ethical integration into society.

The integration of COBOTS into various aspects of society raises important ethical and societal considerations that must be addressed. For instance, there are concerns about the potential for COBOTS to exacerbate inequality by displacing certain groups of workers or reinforcing existing biases. Additionally, questions surrounding data privacy, algorithmic transparency, and accountability come to the fore as COBOTS increasingly rely on AI and machine learning algorithms.

Moreover, the broader societal impact of widespread automation, including changes in employment dynamics, income distribution, and social cohesion, necessitates thoughtful consideration and proactive measures to ensure that the benefits of COBOTS are equitably distributed and inclusive.

Looking ahead, the future of collaborative robotics holds tremendous promise for innovation and progress. Continued advancements in AI, sensing technologies, and human-robot interaction will further enhance the capabilities and versatility of COBOTS, enabling them to tackle increasingly complex tasks and challenges. Moreover, human-centered design principles will play a crucial role in ensuring that COBOTS are intuitive, accessible, and inclusive, catering to diverse user needs and preferences. Collaborative ecosystems comprised of industry stakeholders, researchers, policymakers, and end-users will drive the development and adoption of COBOTS, fostering a collaborative approach to

innovation and problem-solving. Ultimately, the future of collaborative robotics is one where humans and machines work hand in hand to unlock new possibilities and shape a better world for generations to come.

In conclusion, Collaborative Robotics represents a pivotal moment in the evolution of automation, marking a departure from the traditional paradigm of robotics towards a more collaborative and inclusive future. The integration of COBOTS into various industries has the potential to revolutionize workflows, enhance productivity, and improve the quality of life for individuals around the globe. By embracing the transformative power of COBOTS and prioritizing collaboration,

innovation, and human well-being, we can build a future where technology serves as a catalyst for empowerment and enrichment for all.

Need help with COBOTS and Industrial automation? Reach out to us

We’re always here to help, Explore AES’s expertise in Industrial automation capabilities! Step into the future with AES – Your End-to-End, Industrial Automation Partner.