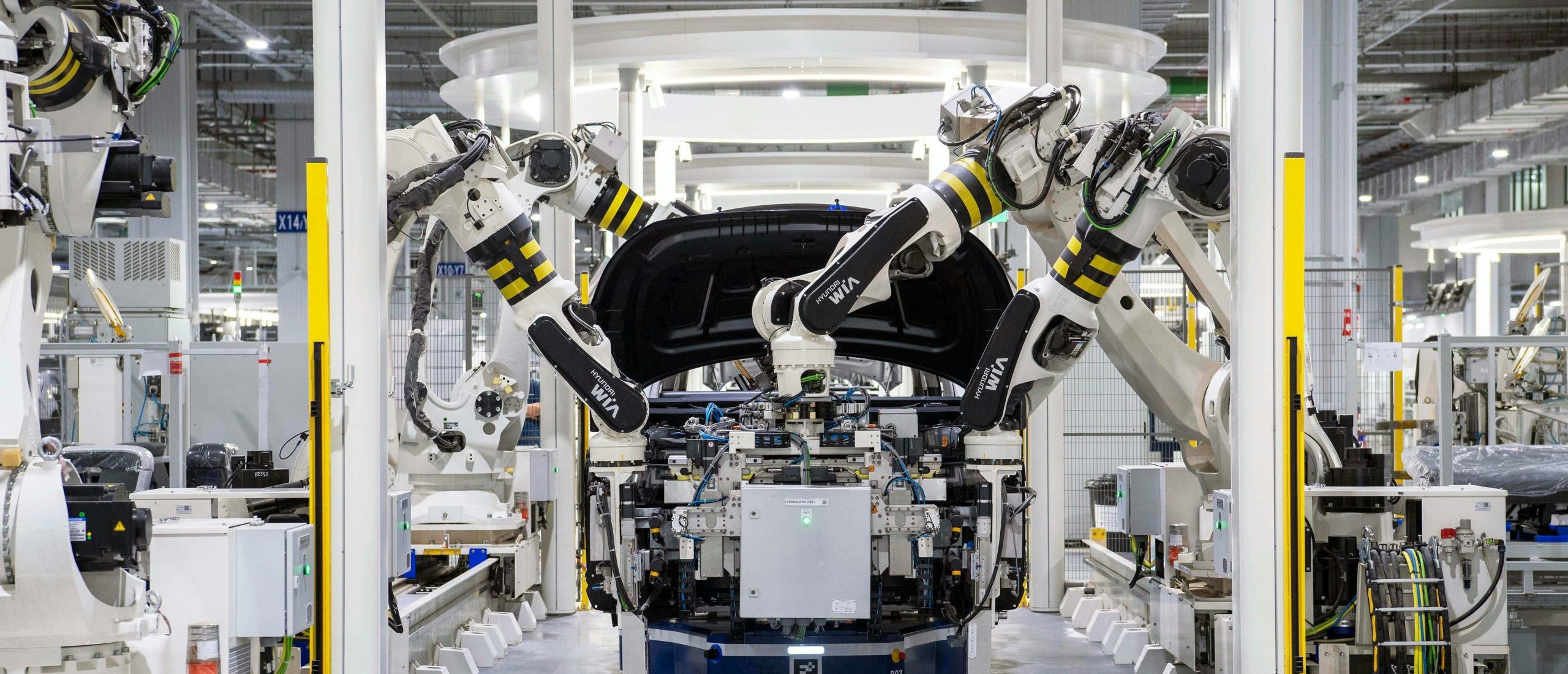

AES, a leader in industrial automation and engineering solutions, announces the successful grant of a retrofit project focused on enhancing production capabilities for the front and rear fascia of an electric vehicle (EV) manufacturer’s manufacturing unit. This project represents a significant advancement in automating key components critical to EV production.

The retrofit initiative will deploy advanced automation technologies tailored for the manufacturing of front and rear fascia components. AES, renowned for its expertise in custom automation solutions, will integrate state-of-the-art robotic systems, precision control mechanisms, and smart manufacturing techniques to optimize production efficiency.

“This retrofit project underscores our commitment to driving innovation in industrial automation,” said Akhil Seth, CEO of AES. “By leveraging our technological prowess, we aim to enhance our client’s manufacturing capabilities and support their leadership in the rapidly evolving EV market.”

The project involves making changes to conveyor systems, storage systems, and industrial robots tailored for producing front and rear fascia components. The goal of this retrofit project is to modify the existing production line so that it can handle the new designs of the front and rear fascia, which come in different sizes and shapes.

“Our collaboration with AES reflects our commitment to advancing production efficiency and product quality,” stated (Client Representative) from the EV manufacturer. “This strategic initiative will enable us to meet the growing demand for electric vehicles while maintaining high standards of manufacturing excellence.”

AES continues to lead in delivering innovative automation solutions, transforming industrial processes to meet the specialized requirements of the electric vehicle manufacturing sector.

For more information about this project and its automation solutions. Please contact us at sales@aesgs.com.