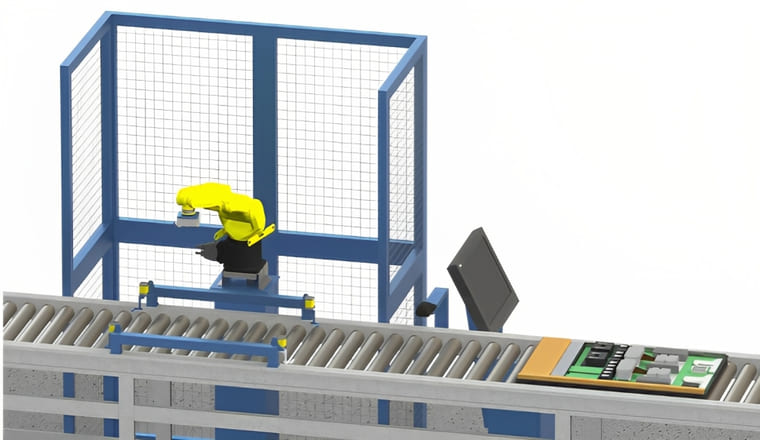

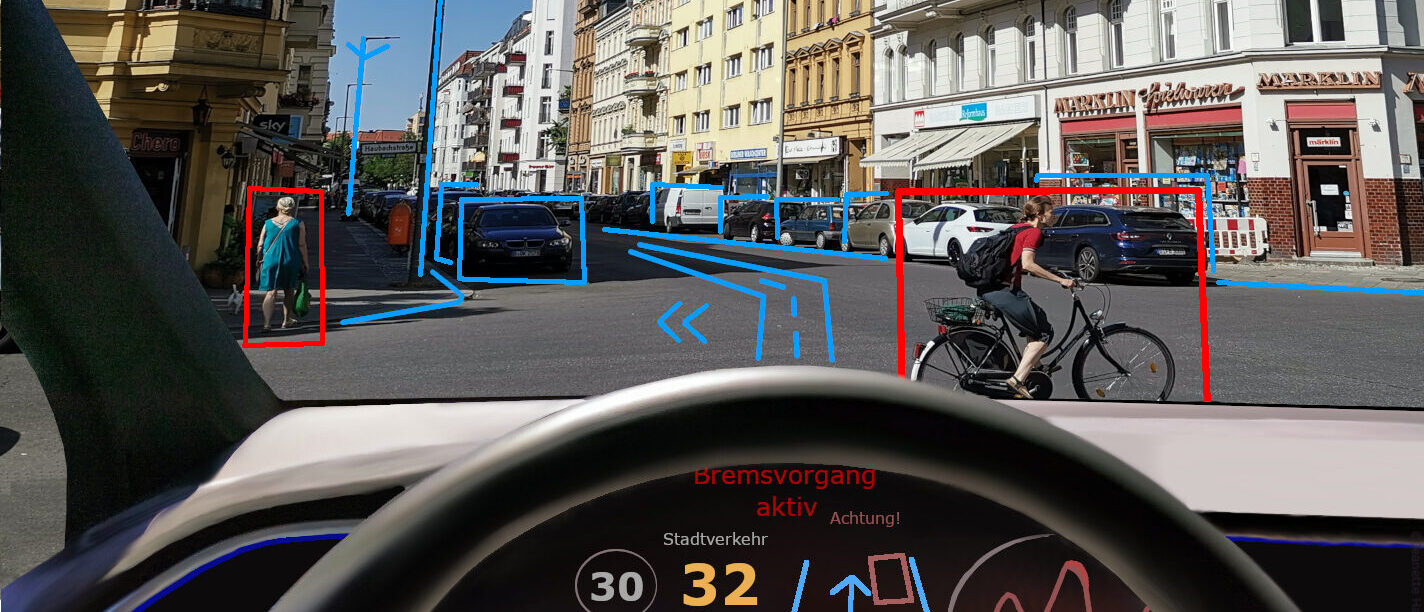

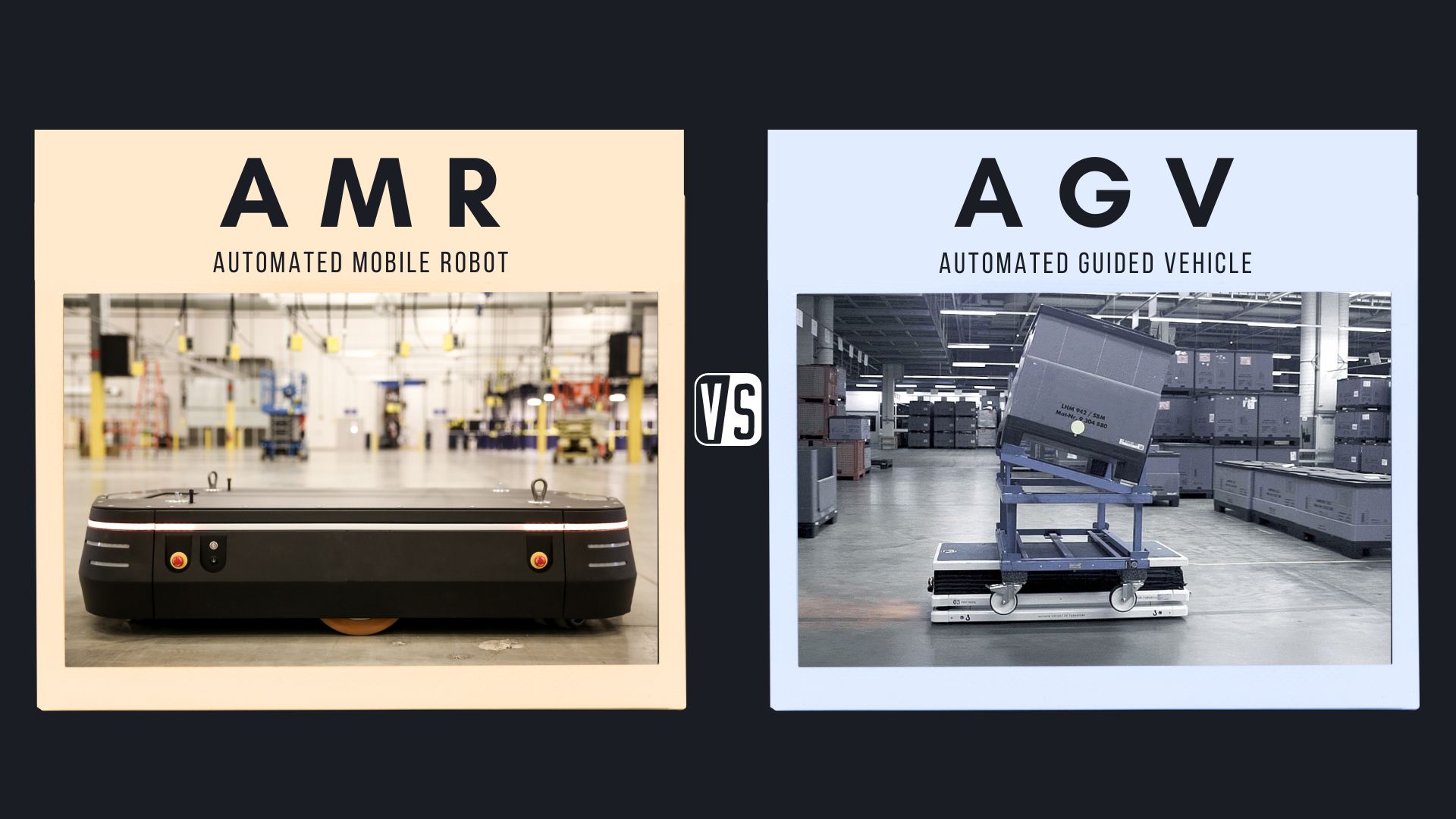

AES applies machine learning and events-driven industrial automation to initiate proactive problem detection, troubleshooting, and minimize mean time to repair.

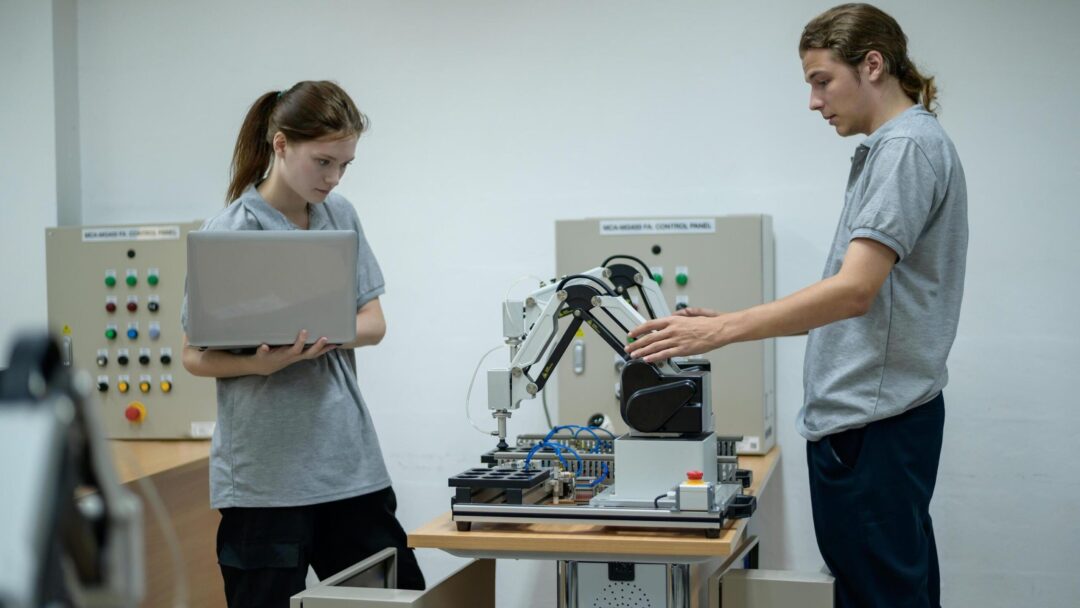

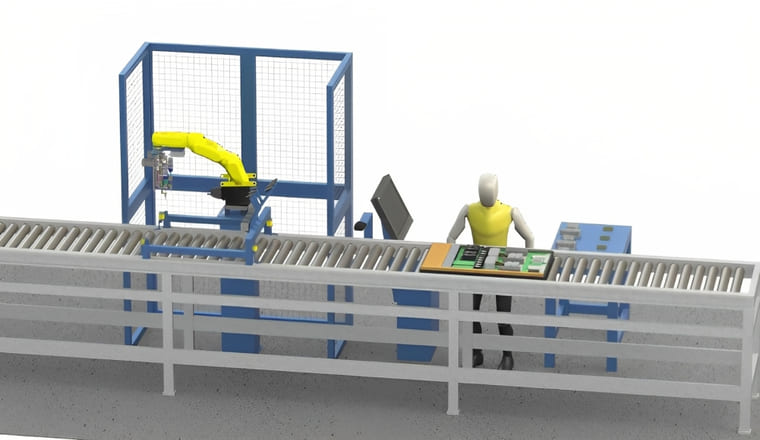

Mechanical Engineering Professional with 31 years of global experience [12+ years of experience at onsite US] in Mechanical design for Automation, New Product Development, Windows & Doors, Automotive, Special Purpose machines, Material handling equipment, Corrugating machines, Industrial Machines, Jigs & fixtures, Project Management & Delivery Management.

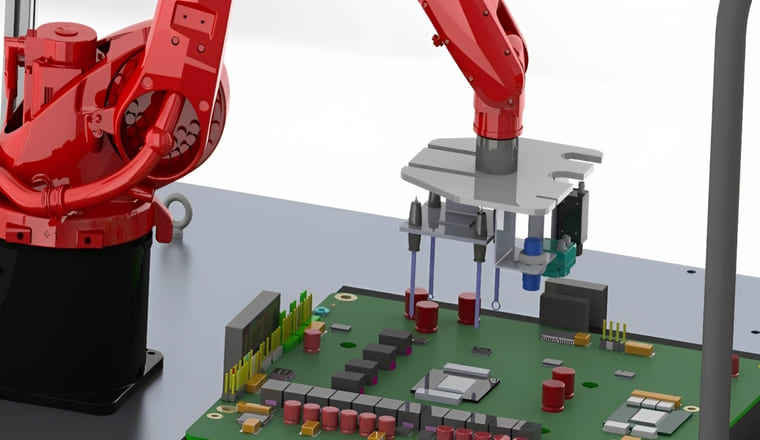

Raju has In-depth knowledge of mechanical design for new product development, packaging machines, special purpose machines, jigs and fixtures. Experience in design through prototype building of new product

development and have extensive knowledge in manufacturing processes and adopting it in concepts/design. He has professional excellence in project planning, scheduling, monitoring & execution of projects minimizing incidences of time & cost overruns.