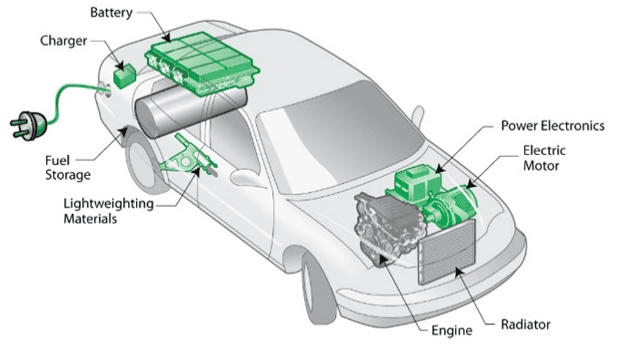

Since inception AES has been involved with some of the most challenging and successful automotive Interiors and Exteriors engineering projects both at OEM, Tier-1 and Tier-2 supplier level. Our unique engagement model allows us to cater to a large vehicle integration project for an OEM to small product validation for a supplier with same speed and agility irrespective of the size and duration of the project. Unlike other verticals, automotive engineering projects require quick turnaround, manufacturing information, exposure to standards and cost sensitivity, all in one go. AES offers a single window for all automotive product design requirements

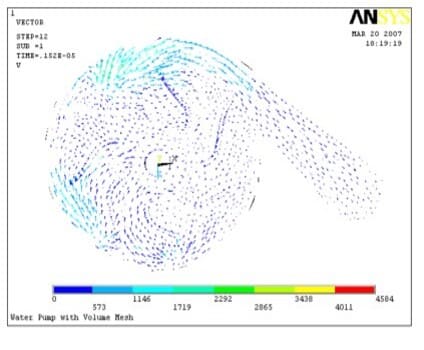

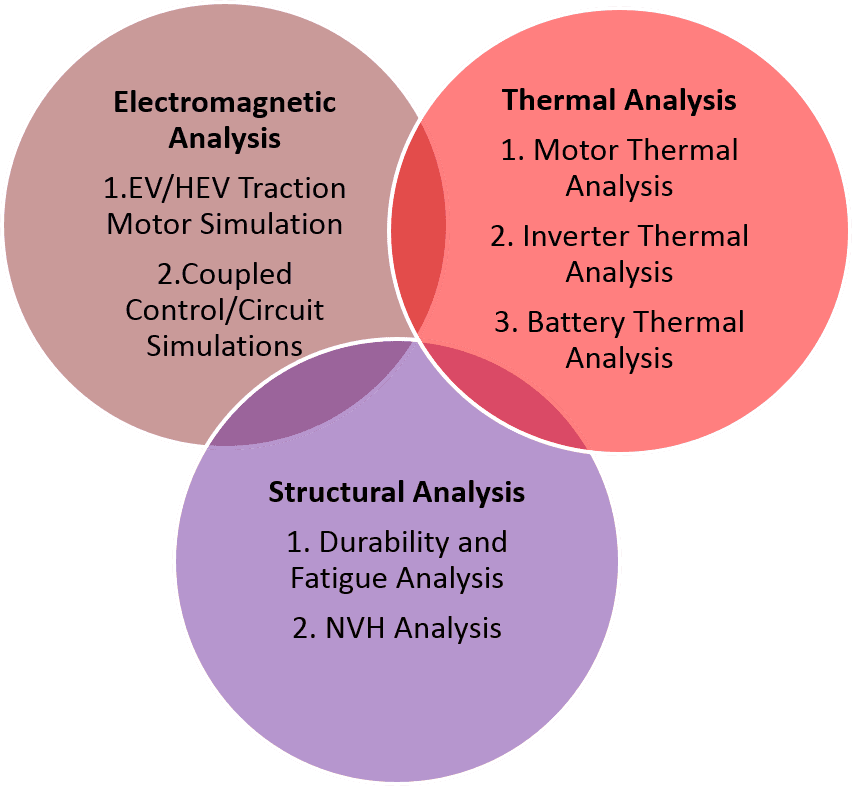

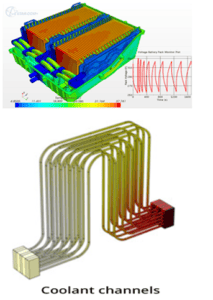

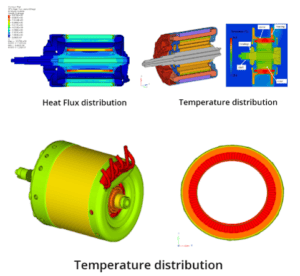

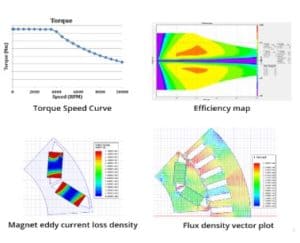

Motor thermal analysis are done as follows:

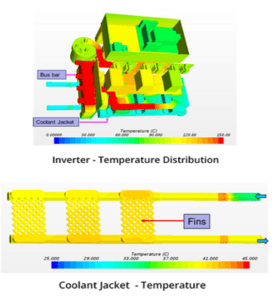

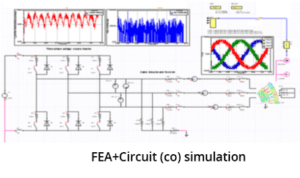

Our Inverter services includes:

Ask me a question, I'd love to hear more from you.