We offer Fenestration Design Services by optimized design using FEA and CFD tools. The Design process is executed to satisfy various codes as follows:

We offer optimized design, carefully analysed using FEA and CFD tools. The Design process is executed to satisfy various codes as follows:

Apart from the codes, we also test the design for extreme temperatures to ensure the reliability of product on a long run. We perform Stress and Creep Study in various parts due to tolerances, Snap fits Weather shield (Rubber) design, Adhesive strength study where ever applicable.

Water discharge through the window weep system are studied under high vacuum pressures are studied. Various sill and Key designs are studied to ensure maximum discharge through the system in minimal time.

Capabilities includes the following

IG Analysis is performed to ensure the Glass, spacer and spacer sealant are adequate to withstand testing under design pressure. Glass are the most critical part of IG, its important to make sure that they don’t fail in Tension, compression or shear. Strength of glass are generally different in edges and surfaces. We carefully study such criteria’s and design the IG. Sealant failure are also most likely to happen especially when there are high relative movements of either side glass due to high overall deformations.

Benefits: Glass, Spacer and sealant adequacy is arrived by this process.

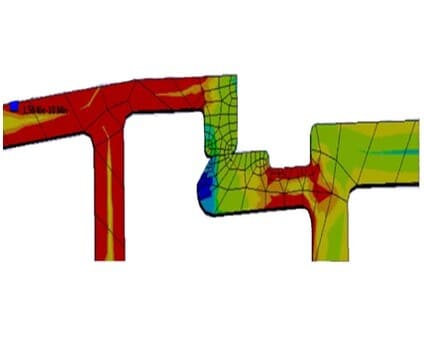

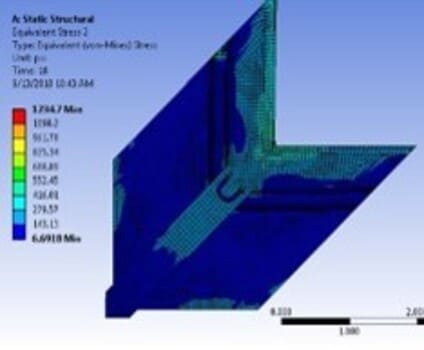

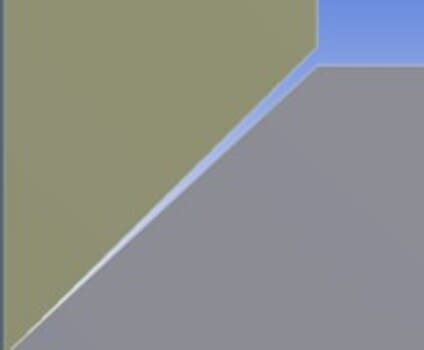

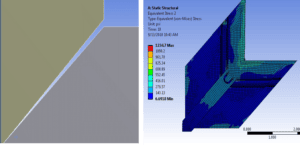

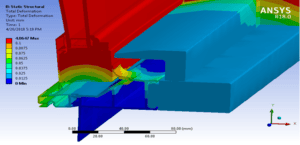

Adhesive analysis for various Tolerance of Miter cut: The frame corners are connected by a Miter cut. Miter cut generally have angular tolerances due to which during the assembly and glue filling, the frames are torqued by fixtures to the extent to close the miter cut gap. Once the glue is filled and the torqueing forces are released, the glue is stressed additionally to other stresses which it is subjected during its functionality. We study problems to such details to achieve the best Designs. Below image in left shows the gap generated due to the miter cut tolerance and the beside image shows the stress distribution in adhesive.

Benefits: By this study, we are able to identify the maximum tolerance level in the mitercut without compromise in product performance.

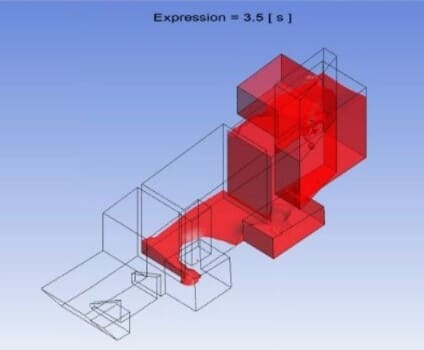

CFD analysis of Water Weep system: A standard test where a vacuum pressure is applied at water inlet and water is made to pass through the system is a mandatory to ensure that the water does not remain stagnant in the window system. Different Design Iterations are run to ensure the best flow rate is achieved through the system. Very stringent assumptions are taken to match the Test results. 3D printing of the different models are done and tested to cross compare with the CFD results. Below Image shows flow of water through the system at different time frame.

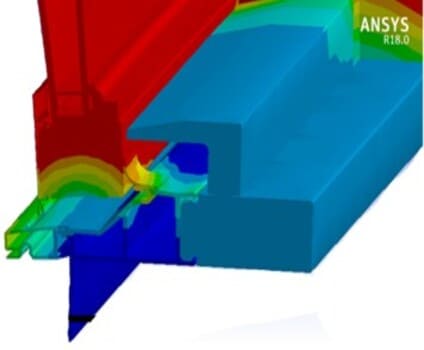

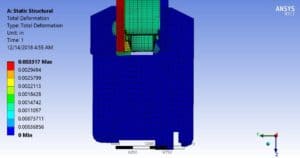

Hardware Analysis Hardwares in door and window structures are very significant as the Frames are much weaker compared to the hardware components and the locations where the frame comes in contact with hardwares are prone to failures. Such localized areas need to be studied in detail and Ansys assists such simulations.

Benefits: Contact stresses can be determined, remedial actions can be simulated before building prototype.

Adhesive analysis for various Tolerance of Miter cut: The frame corners are connected by a Miter cut. Miter cut generally have angular tolerances due to which during the assembly and glue filling, the frames are torqued by fixtures to the extent to close the miter cut gap. Once the glue is filled and the torqueing forces are released, the glue is stressed additionally to other stresses which it is subjected during its functionality. We study problems to such details to achieve the best Designs. Below image in left shows the gap generated due to the miter cut tolerance and the beside image shows the stress distribution in adhesive.

Benefits:

Hygroscopic Swelling Study: Hygroscopic swelling is a phenomena where a diffusing liquid substance, gets absorbed into a solid medium and causes expansion of solid medium. A test is run to identify the hygroscopic swelling coefficient and Diffusion coefficient. Diffusion coefficient is an empirical which is a function of ease of absorption in any solid medium.

Benefits: Relative expansions in a door or window due to strain and hygroscopic expansion can be studied and appropriate design changes can be made to arrive at an ideal door design.

Ask me a question, I'd love to hear more from you.